New Ferag mailroom components are being added to existing equipment in a “reshuffling” of resources at Fairfax Media.

The Australian publisher is upgrading plants at Ballarat (Victoria), North Richmond and Newcastle (NSW) and Fyshwick (ACT) as part of preparations for the closure of its two biggest sites at Tullamarine and Chullora next June.

New Ferag collating and inserting equipment is being added to the upgraded NSW sites where existing Ferag equipment is to be supplemented by that from the Tullamarine (Melbourne) site which currently prints metro daily The Age.

Like the soon-to-be-closed Chullora print site, Ballarat has Müller Martini mailroom equipment.

Fairfax group director for print and distribution Bob Lockley says group products have been reorganised to optimise line utilisation. The group expects the decentralisation to lower production costs by “around 60 per cent”.

Ferag is integrating components from Tullamarine – mainly MultiDisc winding systems and MSD MultiSertDrum inserting – into the facilities in Fyshwick, North Richmond and Newcastle in Australia, as well as Wellington and the new Auckland site in New Zealand, a process which has already begun.

It will also balance components' control software across several system generations.

While Fairfax has committed to publishing printed newspapers for as long as they are profitable, Lockley said in Penang last month that they were “well down the road to providing for digital only”.

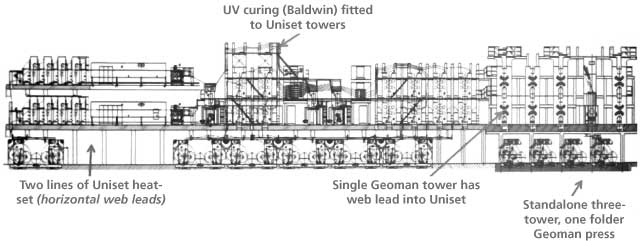

The North Richmond press (pictured) will be “really flexible” with conventional heatset and UV-curing running alongside both single-width and double-width coldset towers, the latter sourced from the Tullamarine site. Print runs for the Sydney Morning Herald are expected to be about 150,000, compared to 300,000 copies at its peak.

On the print side, UV was earmarked for “a few more sites” and Lockley admitted Goss’s automated Magnum Compact had also caught his attention for some regional sites. With double-width, facilities for flexible web widths had made a “big difference”.

At the ASEAN Newspaper Printers delegate conference in Penang, Malaysia, Lockley explained that the restructured group – which currently includes 431 mastheads, 337 websites, 100 apps, seven radio stations and 20 print sites – would be “diversified, lean and agile”.

He said the group had got rid of silos, halved the senior management team, and was “outsourcing everything we can”. Cost cutting has been “fairly severe” and would reach $250 million in the 2014-15 financial year as the workforce came down from 11,000 to under 9000. One thing that has not been cut back is training.

“Just watch us for a while,” Lockley says.

Pictured, top: Mailroom components are prepared for despatch to Fairfax from Ferag’s plant in Hinwil, Switzerland

Below: The extended and reconfigured manroland press at North Richmond and (bottom) early stages of building work there

On our homepage: Lockley answers questions in Penang

Comments