A new Colorman e:line press installation will be a pilot for manroland’s inhouse-developed ink density control system.

Installation of the two-tower e:line 50 with autoprint at Mediengruppe Oberfranken in Bamberg, Germany, is set for November, and it will take over production two older KBA presses by the following April.

The Bamberg print site produces eight different daily newspaper editions, and the 32 page press – rated for up to 50,000 cylinder revolutions an hour – will print about 150,000 copies a day. With a lot of job changes for editions, the autoprint features will help to reduce makeready and waste, allowing a parallel makeready, with only three operators.

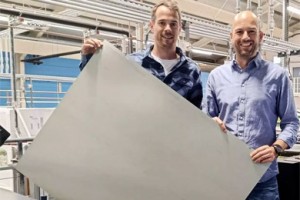

The press will also be equipped with manroland’s ControlCenter operation system and equipped with MobilPad. The site will also be a pilot project for a new manroland web systems ink density control, which uses a moving head camera and micro marks. The company says development of the system under the InlineControl brand follows field experience of ink density control on commercial presses.

Plate delivery for the APL robots will take place at the console level with those for upper levels raised with an elevator. It will be installed in a rotunda-shaped annexe with glass façade that symbolises two piled paper rolls.

Print business unit managing director Joerg Schild-Mueller says the press offers “everything we require” to further strengthen a successful business concept: “The short project duration and the fast decision from our side show how strongly we are convinced by the concept.”

Although Mediengruppe Oberfranken has several manroland commercial presses, the Colorman e:line 50 is its first newspaper press from the maker.

Comments