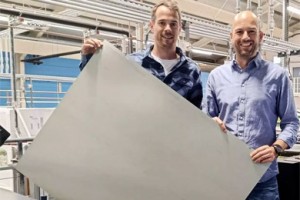

Norske Skog Australasia has officially launched its “new and exciting” Vantage LWC stock, produced following an $85 million project at its Boyer mill.

One of two newsprint machines there has been converted produce about 140,000 tonnes of the new catalogue and magazine paper a year.

Customers toured the new facility today – ahead of an official opening on June 11 – with regional president Andrew Leighton thanking all those associated with the conversion and the new product’s development.

“Vantage is the only locally produced LWC on the market and has already run successfully on a number of major printing presses,” he says. “It is a new and exciting product incorporating the latest advancements in paper making and coating technology.”

He described it as “truly a world class LWC”, is ideally suited to the modern high speed presses used in this region.

Leighton also thanked federal and Tasmanian governments for supporting the project “together with the significant capital investment by our owners”.

“This project is a key component of our regional strategy to transform the business from being wholly a newsprint producer to having a more diverse future in paper, fibre and energy.”

He congratulated the Boyer team for “painstaking work” in converting an existing machine through the addition of state of the art new equipment. “The project has also been strongly supported by paper machinery supplier Metso, our new on-site coating filler supplier Omya, design engineering partners Beca Amec plus many local Tasmanian contractors and suppliers. In addition we have drawn upon Norske Skog’s global knowledge and expertise.

“This has been a real team effort across our entire business and literally hundreds of people have been involved in one way or another to make it a success.”

The machine conversion involved the addition of new coating, drying and calendaring equipment, the installation of a new winder and extensive building works, upgrades to existing equipment and process changes.

Sales, marketing and logistics vice president Andrew McKean said the project had generated “significant interest and support” from local printers, publishers and retailers keen to see the return of a local supplier.

“Having locally produced LWC means our customers will benefit from shorter lead times which in turn means lower inventory, less delays and greater flexibility,” he said. “Vantage is a great product in its own right and when combined with all the local benefits we believe it’s going to be a real winner”, he said.

Comments