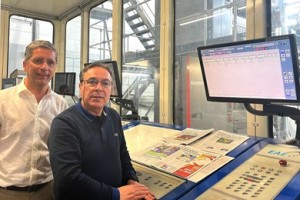

Controls and drives have been upgraded on two Goss Magnum presses at Advance Central Services Michigan’s Ann Arbor facility.

Harland Simon has replaced GMI ink desks, folder SLC500 PLCs and Allen-Bradley 1395 drive modules, while centralising compensation, ink and damp control.

The company has completed similar projects at Advance Central Services Alabama’s production facilities in Huntsville and Birmingham, which also support commercial print.

Four P6000 desks are interfaced to existing GMI inkers for ink control, and now serve as the central location for couple trim, damp pan and ink duct roller adjustments.

Allen-Bradley CompactLogix PLCs – with its RSlogics 5000 diagnostic software – and Allen-Bradley PowerFlex drive modules were used, with all the diagnostic software is available at a maintenance PC.

Six new 200HP PowerFlex regenerative DC drive modules replaces aging or obsolete 1395s, and obsolete SLC500 master drives PLCs were replaced with CompactLogix PLCs and reconfigured the new drive master PLC to enable master/slave selection and operation. A RIPSet system calculates ink presets and there is also upper-level management, monitoring and calibration of register presets.

In addition to its commercial print customers, Advance Central Services Michigan supports MLive Media Group with production, distribution, purchasing, accounting, technology and human resources. The company prints the Grand Rapids Press at its Walker production facility, along with several other titles, including the Kalamazoo Gazette and the Muskegon Chronicle.

Comments