While retrofitting the latest control technology to its 20-year-old Brisbane presses, News Corp Australia has brought a new manufacturing culture to the print site, writes Peter Coleman

The metal is more than 20 years old, but appearances can be deceptive.

Behind the blue cabinetry of the manroland Newsman presses at News Corp Australia’s Brisbane print centre, control technology is state-of-the art and a new facilitative culture inhabits the people who run it.

The latest manroland and QI Press Controls systems are only part of a story of regeneration which tailors newspaper manufacturing facilities to the reality of today’s shrinking print publishing environment without installing new presses.

“We’ve taken a press they had worked on for 20 years, pulled the electronics out of it and put new in; the printers are back in the quiet room, looking at the same blue metal that’s always been there but it works completely differently,” says national production and logistics director Geoff Booth.

And so do they: Cultural change has been fundamental to the transformation and consolidation which will see the nearby Gold Coast print site closed and almost 100 jobs shed. Notable is a switch from “directive” to “facilitative” leadership which sees management step back from telling printers how to print and focus on providing them with “a framework for succeeding”.

Says Booth, “The changes have been enormous – the work people do and how they do it, and how they are managed or rather, led to an outcome – that’s a really big shift and is by no means done yet.”

A change not everyone could make, and there is acknowledgement that while most have stepped up, there have been others who have been provided with the opportunity to leave. Across the two sites, almost 100 have taken redundancy, first in July 2012 when an underutilised Murarrie press was closed, enabling the electrical replacements and disruptive maintenance work to get underway last April.

Structural changes in leadership – where total numbers came down from 38 to about 18 – followed late last September after announcement of the progressive Gold Coast shutdown.

He says printers have done “an amazing job” and praises especially the “extraordinarily progressive” culture of the Gold Coast team of whom only about 15-17 will move to Murarrie.

The two-year $13 million programme at News’ print site at Murarrie, just southwest of the city’s Gateway arterial and its giant twin river bridges, has its origins with Booth’s appointment and his vision for a different approach to producing newspapers.

With a financial rather than a production background, Booth began his 35 years with News at the Gold Coast Bulletin, and worked for the group’s New York Post and as general manager of the Sydney Daily Telegraph before taking on his present role four years ago.

New presses were going into Sydney at the time, “and the view was that you didn’t want to do things the same way we always had,” says Marcus Hooke, recruited from toothpaste maker Colgate to lead a focus on lean manufacturing processes.

“It was Geoff’s vision move away from a newspaper mindset, to running it as a manufacturing operation using what are lean practices to turn it into a more efficient place.

“What we do as a manufacturing process is no different to making a can of Coke or a loaf of bread, without discounting the quality of our journalism or our content. For our part of the business, it’s pure manufacturing and there are things we can learn from companies such as Toyota which have been lean for 20 years.”

What’s different from the Sydney situation is that instead of the new Geoman lines, the Brisbane site – which was printing metro daily the Courier-Mail and The Australian and suburban titles – had four of the oldest large newspaper presses in the country, manroland Newsman presses from a giant order placed in 1987.

With Adelaide, Melbourne, Sydney and Perth – and presses for Wapping, Knowsley and Glasgow in the UK – they were part of a $1 billion order placed not long after Rupert Murdoch’s acquisition of the Herald & Weekly Times and ahead of a 1990 financial crisis which famously came close to unravelling News Corp altogether.

A 4/4 tower had been added to each in 2005, and lately the four nine-cylinder satellite units of the Murarrie presses – designed to print four colours on one side of the web and two on the other – have been paired to enable 96-page all-colour tabloids to be printed through the week, with two satellites split at weekends to print up to 128 pages, but with 32 of those limited to spot colour.

A necessary control upgrade project – planned a couple of years back – involves two core areas: manroland web systems is replacing drives and control systems to provide much of the company’s autoprint functionality – including inline control systems, production planning, start-up automation, monitoring and reporting – while QI Press Controls has installed its IDS closed-loop colour density control and register systems.

There are a host of benefits, not the least of which is improved reliability from the replacement of the original Reliance drives – freeing up parts for those still in use in Adelaide, Melbourne and Perth – plus reduced waste and better colour control.

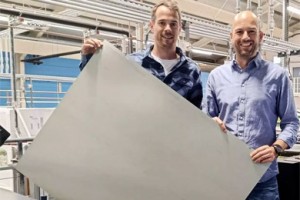

The manroland order with its new tablet-based mobile controls – complicated by the need to adapt software for a shafted press – was the world’s first and accounted for half the global orders when announced at IfraExpo in Frankfurt in 2012. It enables each press to be controlled from a tablet, with smaller units available for use in maintenance.

News is also the first user of QI’s IDS system in Australia – since also ordered by Fairfax Media for the North Richmond, NSW, site where metro daily the Sydney Morning Herald is to be printed – and already has the system running successfully in Sydney.

Consistency of colour reproduction from press to press and across the country, is top of the list for justification – Booth cites matching the Commonwealth Bank’s tricky gold branding as an example – but reduction in start-up waste and ink usage contribute to a “significant business case”.

Hooke says experience in Sydney over the past nine months – where “printing by eye” had driven a tendency to over-ink – is really good: “Pressmen wanted to tinker at first, but have learned to trust the technology and just watch it,” he says. “Again it’s a cultural change.”

Ink usage is “well down” in Sydney, with a reduction of about 100 copies in start-up waste, “adding up to quite a bit on every start”. On manning, the Sydney experience has been that printers are much more able to relieve each other during meal breaks – something that would have been unheard of before – though it is not clear whether that will translate from the more-automated Geomans to a Newsman site such as Brisbane.

The programme has been accompanied by an upgrade in lighting, reducing power consumption, and changes for the reliability team including new planning and scheduling software.

Booth, like site leader Mike Molloy – a former compositor who returned to Brisbane a year ago after running News’ Gold Coast and Perth print sites – has seen the changes which have taken place in the industry over his 35 years with News.

Even the last year, and with the changes taking place, Molloy says newsprint tonnage through Brisbane has fallen about ten per cent to 700 tonnes a week.

The Gold Coast site, upgraded in 2003 with a nine-tower KBA Comet press was a response to an advertising boom, 400-plus page Bulletin editions with 200 pages of real estate and “tons and tons of advertising”… a contrast to today’s papers which are not much more than half the size and with circulation down from about 85,000 to nearer 50,000 copies.

Now the Gold Coast print site is being closed, with the press and mailroom equipment likely to be mothballed, as production of the still very vibrant daily newspaper – and the 25,000 copies of the Daily Telegraph for local and northern NSW markets – is brought to Murarrie.

The decision to close what they says is “the best equipped site in the country” was a difficult one: “It became compelling when you considered the additional management and property overheads,” Booth says. “When we had the ability to run four presses here, to move everything into the Brisbane site just made financial sense.”

Weekly and most daily editions have now moved to Murarrie, with Hooke says, “just the last few products” being printed there.

At one point, time for staff to attend “a very formal process of training” was created by buying press time at the Fairfax Media’s plant at suburban Ormiston. The Certificate 3 (Lean manufacturing) for all staff and Certificate 4 (Competitive manufacturing and leadership) for a select group mirrors what has News has done around the country. While crafted by external contractor Leadership Management Australia to ensure relevance to the jobs of printers and publishers, it delivered a portable qualification with a focus on personal as well as professional goals.

“That’s been part of the buy-in, that if they moved to another job in another industry, they had a nationally-recognised qualification,” he says.

Classroom training – and a requirement to put in some personal time – was “on top of their day jobs, not instead of them” but the programme has been well received: “There has been a lot of personal growth that staff have taken out of the training as well,” says Booth. “I’ve been to most of the graduations around the country and to actually see the changes in people and their pride in it has been very encouraging.”

While the programme acknowledges continuing change in a shrinking industry, Hooke says a real advantage is that News is a business which really values print, “something we can articulate to people.

“There is no way this project would have happened without that belief in newspapers: This whole project has cost $13 million, a significant investment in what a lot of people consider to be a dying industry.”

Comments