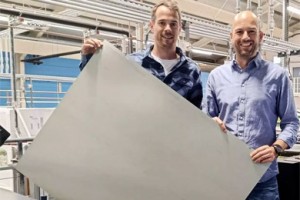

Kodak is expanding its CTP offering with new automation retrofits and the availability of its ThermalNews PT digital plate in the Americas.

The thermal newspaper plate was introduced to Europe two years ago, and eliminates the preheat and prewash steps from processing. Kodak says that as “the industry’s only processed plate” of its kind for newspapers, it saves up to 60 per cent of power consumption and halves water use.

It has the same stability, quality, run lengths and imaging speed as ThermalNews Gold digital plates, with runs of up to 200,000 claimed without preheating, and 350,000 with.

It joins the process-free Sonora News portfolio of plates that reduce environmental impact and related costs. Production in Columbus, Georgia, is being upgraded to meet demanmd.

Kodak has also announced an add-on single cassette unit for existing Trendsetter and Achieve platesetters to allow automated loading and unloading of up to 240 plates with slip sheet removal and automatic rotation. This will enable platesetters to be run without personnel for up to seven and a half hours.

Compatible units include the Trendsetters Q400, Q800, Trendsetter News, and Achieve T400 and T800. The unit has a footprint of 2330 x 2800 x 1860 mm and shares the same engine and unload table as the platesetter.

Kodak says it is currently available in “controlled sales production environments” with wider global availability promised later this year.

Comments