Goss is to deliver an end-to-end hybrid print system including inline finishing for German print service provider Mohn Media.

The Gutersloh, Germany, print service provider plans to have the new system – based on a 24-page Goss Sunday 2000 press with a 1.5 metre web – in operation before the end of the year.

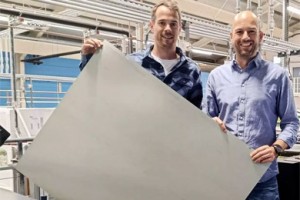

Ability to source the wide-web, single-circumference press and complex inline finishing equipment from a single supplier was of “key importance”. Goss will supply the five-unit Sunday press with inkjet personalisation and inline coating, glueing, diecutting and prefolding components from its Contiweb Vits subsidiary.

The press will have a 1450mm web width, semiautomatic plate loading, a pinless folder, Contiweb CS zero-speed splicer and Ecotherm dryer, as well as an additional made-to-order web drying configuration featuring further chill rolls and a remoistening unit.

Mohn Media chief executive Axel Hentrei says the intention is streamline processes to improve production flexibility: “Once the new Goss press line is up and running, we anticipate significant time-savings on regular jobs as well as less waste and a more efficient use of resources in general,” he says.

The 1450mm wide/six-pages-across format will deliver up to 65,000 iph combined with the flexibility of the single-circumference (two-pages-around) format.

Hentrei (pictured) says the sophistication of the configuration calls for a “safe pair of hands” from start to finish: “We understand very well how important it is to have the right skills, experience, process knowledge and attention-to-detail,” he says.

Based in Güttersloh, Mohn Media has as its clients renowned publishing houses, as well as industrial and service companies, leading European consumer brands, retailers and mail order companies.

Comments